Below is a guide (pdf) to understanding and specifying the various categories of architecturally exposed structural steel (AESS).

Click HERE to view the giude to understanding AESS - AESS-Modern-Construction_1.pdf

List of SOME Prior AESS Projects

[The TEAM we have assembled for AESS jobs has worked with us many times before, in varying degrees and proportions, as the individual job needs dictated. We have been doing AESS work since 1991 as this list will verify. This document is intended to support any project requirement as to AESS experience set forth in your project specs. Of course, this list is only of the LARGER projects we've done; not all AESS work we've done in total]

Hudson Yards-----Building Tower “C”, NYC, NY (2017-2019)

Scope: Embeds & AESS Podium Steel System; more recently; 21 trusses in Category #4 AESS solid steel for huge glass windows. 15HY Penthouse-curved 40' beam in Category #4 AESS throughout.

One Vanderbilt, NYC, NY (2018-2019)

Fabrication of Major Mullions in Caterory #4 AESS solid steel for Podium.

NYU Langone Medical Center—Kimmel Pavilion, NYC, NY (2016-2017)

Scope: AESS Steel Frame System

Hudson Yards-----Building Tower “A”, NYC, NY (2017-2018)

Scope: 68 Floors---Embeds for AESS Steel System.

Museum of the Bible (MOTB),---Museum in Washington, DC (2017)

Fabrication of Major Plates in Category #4 AESS solid steel for Skylylight System.

Alexander Court, Alexandria, VA (2016-2107)

Scope: Entire Retro Clad System; includes AESS elements.

Capital One Building, Pennsylvania (2016-2017)

Scope: AESS Portal Steel System.

56 Leonard Street, NYC, NY (2016)

Scope: Stainless Steel AESS Entrance System.

Columbia University, Jerome L Greene Science Center, NYC, NY (2016)

Scope: Curtainwall AESS Steel System

St. Barnabas Hospital, Livingston, NJ (2016)

Scope: Embeds & AESS Podium Steel System.

VIA—57 West, NYC, NY (2015)

Scope: Sub-truss AESS Steel System.

NMAAHC—National Museum of African American History & Culture (2014-2016)

Scope: Entire Truss AESS Steel System for Façade---Winner of numerous WBC awards.

432 Park Avenue, NYC, NY (2015)

Scope: Curtainwall Support Steel---Major AESS Mullions.

Children’s Hospital of Philadelphia (CHOP)l Buerger Center for Advanced Pediatric Care, Phila, PA (2015)

Scope: Curtainwall Support Steel---Major Mullions---

250 W.55th Street, NYC, NY (2014)

Scope: Exterior AESS Sunshade Fins----all floors.

United Nations Plaza, NYC, NY (2014)

Scope: Retro-Clad AESS exterior ---Major Mullions.

Fulton Center, NYC, NY (2014)

Scope: Major Mullions---Misc steel--AESS.

John Jay College, NYC, NY (2013)

Scope: Podium Steel---Major Mullions—hundreds AESS members.

4 World Trade Center, NYC, NY (2012-13)

Scope: Blast-Resistant Category #1 Podium Steel---Major AESS Mullions---“Largest Ever Made” ---506 members.

Contractor: Benson Global/Tishman

United Nations Building, NYC, NY (2013)

Scope: Stainless Steel Exterior Mullions---Major Mullions Materials.

Contractor: Enclos Corp

One World Trade Center, NYC, NY (2011-12)

Scope: Curtainwall parts & Assemblies; also made stone anchoring systems (all floors).

Contractor: Benson Global/Tishman

51 Louisiana Avenue, Washington, DC (2008)

Scope: Sky Framing System; Massive Frames for Glazing; Innovative Engineering for Enclosing Inter-Building Courtyard.

Contractor: Enclos Corp

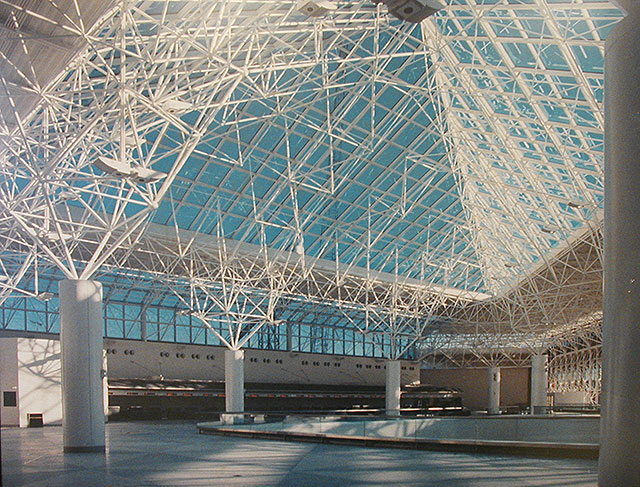

BWI International Airport, Washington, DC (1998)

(Architect William Nicholas Boudova & Associates, GC Omni Construction)Scope: 40,000 structural tubes (millimeter precision) w/ full penetration welds for 200,000 sq ft atrium space frame. ZERO rejections or remediations. Architectural type fabrications as additional components to space frame materials. Miscellaneous machined anchors (stainless steel, aluminum) finished as specified (polished, Tnemec paint or hot dip galvanized). All structural AESS members, re-enforcement metals and skylight connections (such as saddle brackets, wind load anchors, etc.) Over 200,000 lbs. of fabricated “purlin” items (Beam and Channel w/ welded angles and plates, holes, slots, miters, etc.) to accommodate the skylight connections.

Contractor: Harmon Inc./Clark

Novartis Pharmaceuticals Headquarters, Florham Park, NJ (2012)

Scope: AESS Exterior Façade---to Frame Glass Block Wall and Curtainwall Support Steel.

Contractor: Benson Global/Turner

Newseum, Washington, DC (2011)

Scope: Polished Stainless Steel Assemblies and Curtainwall Support Steel.

Contractor: Enclos Corp/Clark

Barclay Center, Brooklyn, NY (2011)

Scope: AESS Truss Fabrication; Misc Steel painted Components.

Contractor: FacadeTech

VCU New Medical School, Richmond, VA (2011)

Scope: AESS Painted Steel Mullions.

Contractor: Harmon Inc./Clark

255 W.54th Street Building, NYC, NY (2011)

Scope: AESS materials for 53 Floors---Stainless Steel brake metal Material.

Contractor: Enclos

Javits Convention Center, NYC, NY (2010-Present)

Scope: AESS-Fabricated Steel Supports and Anchoring System.

Contractor: Enclos/Bovis

American Jewish Heritage Museum, Philadelphia, PA (2010)

Scope: AESS- Exposed Façade Steel Anchoring System.

Contractor: J. E. Berkowitz

New York Times Building, NYC, NY (2010)

Scope: AESS-Fabricated and painted “Cafeteria” Steel-----14th Floor-all exposed to frame huge windows.

Contractor: Benson Global/Bovis

Madison Square Garden, NYC, NY (2010)

Scope: AESS- Stone Truss System.

Contractor: Stone Truss

CitiField, Queens, NY (2009)

Scope: AESS- Stone Anchoring System,

Contractor: Port Morris

BRAC Center, Carroll County, MD (2009)

Scope: AESS Truss System for Window Supports.

Contractor: IKON/Clark

Constitution Center, Washington, DC (2008)

Scope: Misc. Heavy Curtainwall Brackets

Contractor: Enclos Corp

New Yankee Stadium, Bronx, NY (2008)

Scope: AESS- Stone Truss System

Contractor: Stone Truss

Center of Morris County, Florham Park, NJ (2007)

Scope: 325 Complete Trusses with all field hardware. Painted and delivered.

Work value over $450.000

Contractor: Stone Truss Systems

5 Central Park West, New York, NY (2007)

Scope: Glass Curtainwall Anchoring System

Contractor: Benson Global

Washington Visitors Center, Washington, DC (2006)

Scope: Custom Stainless Anchors

Work value over $25,000

Lorton Contracting

New York Times Building, New York, NY (2005-2007)

Scope: Custom Fabricates water jet shapes with Acrylic paint.

Work value over $225,000.00

Benson Global

UVA Arena, Richmond, VA (2004 / 2005)

Scope: Providing Custom Steel Wind bracing.

Borgota Casino Expansion, Atlantic City, NJ 2005 / 2006

Scope: Curve Tubes Clad in Stainless for Casino Entrance.

Work value over $ 198,000

APG Glass

CIRA Center, Philadelphia, PA (2005/2006)

Scope: Glass Façade Steels Parts

731 Lexington Ave, New York, NY (2005 / 2005)

Scope: Providing steel parts for Curtainwall. (2) Canopy entrances above the storefront.

Astor Place, New York, NY (2005-2006)

Scope: Provided a category 3 architecturally exposed radius tubing. Custom curtainwall anchors.

7 World Trade Center, New York, NY (2005-2006)

Scope: Provided steel truss frames for the interior granite installation. Over 10,000 Stainless Steel Anchors for the granite installation.Provided approx. 22,000 black anodized stainless anchors for hand-set stone cladding of this signature building. Anchors are anodized black in order to reduce their visibility in the open joint stone façade.

Work value approx $120,000.

Borgata Casino Hotel (Porte Cochere Skylight), Atlantic City, NJ (2002-2003)

(GC Yates / Tishman, Owner Marina District Development Corp., Architect Bower Lewis Thrower (Philadelphia) and Cope Linder Associates (Philadelphia)) (JV)

Scope: Providing tube steel supports for entry drive. HSS steel is hot dip galvanized and subsequently clad with polished stainless sheet to appear as solid structural stainless. Largest members are 65’ curved segments.

Work value approx $400,000.

West Perry Condominiums, West & Perry Street, NY, NY (2001-2002)

(Arch.: Richard Meier & Ptrs, GC: Gotham Const Corp, Owner West Perry LLC)

Scope: Provided significant quantities of curtainwall support steel and custom flashing for this ultra-luxury residential building. Our work also included modifications to European hardware to make it work given varying field conditions.

Philadelphia International Airport Terminal 1, Philadelphia, PA (2001)

(Architect Kohn Pederson Fox Associates, GC Turner, Owner Philadelphia Airport Authority)

Scope: Provided curtainwall support steel for metal panel cladding of new international arrivals terminal.

State Farm Corporate Complex, Morristown, NJ (2000)

(Architect Gerald A. Voermans, GC/ Owner Gale Wentworth Associates)

Scope: Fabricated 400 truss frames (38,000 sq. ft.) for class A office building.

Gannett / USA Today Corp. Headquarters, McLean, VA (2000)

(Architect Kohn Pederson Fox Associates, GC Clark Construction)

Scope: Fabricated / high-performance painted 80 tube steel supports (43-ft x 8” x 20” x ½” thick wall) for long-span curtainwall. Also supplied 90 barrels of connection hardware. .

Schering Plough K-1 Laboratory, Kenilworth, NJ (2000)

(GC Torcon)

Scope: Fabricated 95 truss frames (16,000 sq. ft.) under extremely tight deadline for new pharmaceutical laboratory complex. Worked closely with both Metro Framing Systems, Inc. and general contractor Torcon Construction while attempting to salvage building closure date.

Work value approx $290,000.

Islip Federal Courthouse, Islip, NY (1999)

Turner Construction (Architect Richard Maier, Owner GSA)

Scope: Detailed and fabricated 135 truss frames (22,000 sq. ft.) for wing wall portion of justice complex. We were replacement subcontractor for Metro Framing Systems, Inc. Turner Construction was extremely pleased with the “rescue” by Metfab and we are now an approved subcontractor for Turner. Designed in a partnership with Richard Meier & Partners, the 12-story building was placed on a podium to give it a presence on an otherwise flat and undifferentiated exurban site. The north façade is faced with stone and pierced by horizontal windows. This building reinterprets the courthouse type to enable it to function as a new kind of civic institution, receptive to public events as well as to the formalities of the judicial process.

Dulles Airport Project, Chantilly, VA (1998)

Scope: Terminal expansion – provided all miscellaneous fabricated tube steel for roofline facade, as well as parts for metal enclosures, wind screens, and ground screen walls.

Secret Service Building, Washington, DC (1998)

Scope: Miscellaneous steel framing. Tube steel truss frames with various angle and plate cross members.

Basilica National Cathedral, Washington, DC (1998)

(Rugo & Carosi)

Scope: Fabrication of 80’ long / ¾” thick stainless steel sub-structure supporting world-renowned 50 ton hand-carved stone sculpture of religious figurines.

J.P. Getty Center Project, Los Angeles, CA (1997)

(Architect: Richard Maier)

Scope: Various angles and stainless steel anchors required. Various welded anchors. High performance coatings such as Tnemic and Ameron-Amerlock.

Washington National Airport, Washington, DC (1997)

Scope: Miscellaneous skylight metal stripping, window lifting racks and custom frames (made of angles, tubes, plates, etc.) provided.

Church of Latter-Day Saints Cathedral, Caracas, Venezuela (1997)

Scope: Typical stainless steel handset anchors with various hardware items (nuts, bolts, dowels, etc.) provided. Under an extremely tight schedule, Metfab produced nearly 10,000 anchors (welded items included) within six days.

International Monetary Fund, Washington, DC (1997)

Enclos Corp (formerly Harmon, Ltd.)

Scope: "Entrance Way" materials. 30'-0" long hot-dipped galvanized framing and approx. 6,000 pcs. of various welded stainless steel clips.

Virginia State Library Project, Richmond, VA (1996)

Scope: Cosmetic Stainless Steel Shapes. Provided approx. 35 pcs. 1/2" thick x 20" wide x 12'-0" long stainless steel custom anchors, welded as required. All Polished to #4 brush finish as required. Also included were custom handset anchors.

Chanel, New York City, NY (1995)

Scope: Approx. 20,000 pcs. supplied of various stainless steel welded anchors 3/8", 1/2" and 5/8" thick and all miscellaneous hardware.

Ronald Reagan Building (Federal Triangle Project), Washington, DC (1995)

(Designer Pei Cobb Freed & Partners)

Scope: Stainless Steel Plug Anchors (various sizes and designs), approximately 25,000 pcs. supplied. Hot Dipped Galvanized Disc Anchors, approx. 35,000 pcs. Handset Clip Anchors (various angles, plates, tubes, etc. - all shot-blasted and painted per specifications provided), approx. 30,000 pcs. Field Connections: Deadloads with Jack nuts (800 pcs), Landing Seats and Embeds (approx. 20,000 pcs.) and Field Fixes. Erection hardware including picking materials, frames for stone transporting, and more. Over 300 "hot-rush" conditions successfully accommodated.

Foley Federal Square Project, New York City, NY (1994)

Scope: Provided approx. 200 custom steel frames for 80' raised rotunda (upper and lower) and 50,000 miscellaneous stainless steel anchors.

Merck Pharmaceutical, Readington, NJ (1991)

Scope: All miscellaneous steel members and frame components (approx. 200,000 pcs.) All loading and picking platforms for erection. All gutter systems for drainage.

BWI International (now Thurgood Marshall) Airport Project, Baltimore, MD (1991)

Scope: Terminal expansion – provided all miscellaneous fabricated tube AESS steel for roof web and metal support for glass ceiling.

This page is under construction

[This was the original architectural rendering of the National Museum of African American History & Culture now standing in Washington, DC. We fabricated the striking AESS exterior frame. Go to www.nmaahc.org for more pictures. ]

Before we can tell you why you should come to Metfab Metals to fulfill all your AESS needs, let’s define this term-of-art accurately. For those unfamiliar with this acronym “AESS”, it is Architecturally Exposed Structural Steel, and includes finely-finished steel members (prepped, welded, filled, blasted, polished, and/or uniquely painted/finished) to be installed so that it is permanently open to the view and touch by all after the job is done.

An even more precise definition is:

Architecturally Exposed Structural Steel (AESS) is steel that is designed for structural sufficiency to meet the primary needs of the building, canopies or ancillary structures, while at the same time remaining exposed to view. It is therefore a significant part of the architectural language of the building. The design, detailing and finish requirements of AESS will typically exceed that of standard structural steel normally concealed by other finishes. [1]

All of us in the construction industry are well-advised to understand this concept better as there are “categories” of this finish which greatly vary the work required----and therefore the cost.

This Guide (see footnote #1 below) was developed to facilitate better communication among architects, engineers and fabricators. It was felt that visual references would help all parties understand the intent of the new AESS documents as applied to the design of structures.[2]

AESS work, though structural, is never covered by sheetrock or otherwise hidden from public view. During construction, or even after the structure is complete, at any floor level or at ground level, one can walk up to this steel member, examine it, touch it, see all its perfection or imperfections [as either can be specified per one of the five (5) categories (grades) of AESS commonly available, and detailed in the manual referenced in footnote #1.].

We here at Metfab Metals first did a major AESS job in the mid-1990’s at the BWI International Airport [Now BWI Thurgood Marshall Airport] outside Baltimore, Maryland. [3]

Since then, we have become highly sophisticated at such specialty AESS work on many small to medium-sized projects, as well as several high-profile jobs, such as New York City’s new World Trade Center, the National Museum of African American History & Culture (“NMAAHC”) in Washington, DC and the expanded VCU Medical School in Richmond. Our COO & founder, Jim Murray, has been an integral part of many early AESS projects in the New York City area, as well as around this country. At BWI Thurgood Marshall Airport , even today you can yet see the structural steel space frame (at the ceiling level) with its threads, pipes and connections in plain view-------- and still shining in its original fabricated & installed condition two decades after erection![4]

Since then Jim Murray, has overseen AESS jobs as varied as the American Jewish Heritage Museum (delivered in the early 2000’s) in Philadelphia and the unique “roof ladder” coverage of an interior courtyard at 51 Louisiana in Washington, DC or the Borgata Casino outside entrance overhang (“Porte Cochere”) in Atlantic City, NJ. The new World Trade Center (WTC4) at the restored Ground Zero in NYC) and the even-newer VCU School of Medicine (Virginia Commonwealth University) are grander and more striking examples of this evolving art-form and this architectural aesthetic. Metfab Metals is rightly proud to have done the AESS components for all these signature projects.

We cannot here on a website page recite all that General Contractors or Curtainwall Suppliers/Erectors or even the Design Teams themselves must necessarily require of the chosen fabricator when AESS has been specified. To effectively execute these AESS contracts, actual shop fabricating is only part of the fabricator’s role. Just glance at the 50-page “Guide” cited above (or the also-excellent AISC guide cited below) and you can get a flavor of all that you will need your selected fabricator to undertake to get the AESS to your jobsite in the pristine condition always specified. A few examples should suffice.

A well-informed fabricator such as Metfab Metals must, among other things, first review the job specs themselves to be sure the “category” of AESS (there are five usually) chosen is what the design team really wants; verify it will best serve the aesthetics of the structure; confirm that it fits the budget of the project and; and finally be certain it’s truly what the Owner envisions. [Frankly, these factors are more often in conflict than you might imagine.] After that (sometimes even as part of those initial discussions), the finish and coatings can still be in dispute and need an experienced hand to interject the real-world factors that might well argue in favor of one particular option or another. The broad spectrum of options for the finish and coatings are too often not covered precisely enough---even in the best or very precise specs. Beyond that, there are considerations such as which type of connections are to be chosen, curves and cuts that make the job optimal and finally shipping and erection considerations. Absent years of practical experience, a seemingly good option is prone to error----or just plain confounding to the actual site problems.

Too often lost in this morass of issues is the one that can break all erection timelines and the one we always insist on focusing the design team to: delivery. Actually this is not a single issue. To put it as briefly as we can here in this space, just look again at what AESS is: “finely-finished steel members (prepped, welded, filled, blasted, polished, and/or uniquely painted/finished) to be permanently open to the view and touch of all…..” To say this requires special handling from A to Z is to understate it greatly and, candidly, to misstate the actuality. Each AESS part must be moved, wrapped, secured, and prepared for delivery in a most careful way so that the pristine “fabrication with spec’d finish” that leaves our shop is the one that stands at the often-remote jobsite after erection. On this issue alone, there is simply no substitute for experience. Our experience on any of these issues is why Metfab Metals is your best choice for AESS.

In 2015—and into 2016—we commenced two new AESS jobs with creative new applications of this aesthetic at Hudson Yards in New York City and at a new high-rise commercial building (multi-storeys of curtainwall) a few blocks away. In researching what was needed to satisfy the specs on these jobs, we went back to several resources (including the above-cited Canadian manual[5]) for very helpful metrics and examples to pass along to the Design Teams, as well as our customers.

Don’t forget that Jim Murray always offers you his personal AESS expertise FREE to you—new customer or an established one--- at the job concept stage to anticipate issues before fabrication, to suggest better ways to order, extrude, cut, drill, paint, finish, even stage and deliver and always to save time and money. For further illustrations of the range of AESS work we have done, look at the various pages of this website. (Our archived 10+ years of Newsletters also often illustrate this).

Call Us; We Have All the AESS Answers!

[Our Space-frame AESS fabrications at BWI Thurgood Marshall Airport from the 1990's]

[Inside the finished NMAAHC museum as it appears for the Grand Opening on September 24, 2016.

Our AESS frames support the unique webbed exterior of this bronze-colored museum].

[1] CISC Guide for Specifying Architecturally Exposed Structural Steel, Canadian Institute of Steel Construction, 2012, 2nd Edition, Page 7, primarily authored by Terri Meyer Boake, , B.E.S., B. Arch., M. Arch., LEED AP. We are grateful to her and this resource for all its very useful insights and clarity. This is a useful tool in both explaining this art, as well as drawing accurate specifications.

[2] Ibid. at p.7 also.

[3] See picture at end of this page herein.

[4] Again---See picture at end of this page herein.

[5] For another outstanding professional manual on AESS, the American Institute of Steel Construction (AISC) has one. Go to www.aisc.org. This resource too can take you through all the concerns and issues you must consider in specifying and then executing AESS fabrications.

List of SOME Prior AESS Projects

[The TEAM we have assembled for AESS jobs has worked with us many times before, in varying degrees and proportions, as the individual job needs dictated. We have been doing AESS work since 1991 as this list will verify. This document is intended to support any project requirement as to AESS

experience set forth in your project specs.]

LaGuardia Airport, NYC (Queens), NY (2021)

Scope: Starting with Soffit Framing; next phases will include AESS Miscellaneous Fabrications. [After the project delays of the 2020 pandemic, we believe the release of this major job is the just the first of many such delayed projects.]

Hudson Yards-----The “Spiral”, NYC, NY (2021)

Scope: Mullion Reinforcements; Embeds & AESS Glass Steel Frames (“Glass Shoes”)

550 Washington Street, NYC, NY (2020)

Scope: AESS Sub-girt Trusses; Miscellaneous Fabrications. For Google’s new Manhattan Headquarters; Retro conversion of St. John’s Terminal, Market Square

Marriott New World Headquarters, Bethesda, MD (2020)

Scope: AESS Major Mullions; Miscellaneous Fabrications.

BL4 Paseo, Boston, MA (2020)

Scope: AESS Curtainwall Support Steel; Matte black finish for 8’ & 32’ interlocking members for open lobby installation.

One Vanderbilt-----NYC, NY (2019)---- 47' foot long Major AESS Mullions---to enclose the ground floor glass lobby (looking out at historic Grand Central Station)----solved logistical delivery issues also for timed drop off of these oversize, finely finished steel members.

Hudson Yards-----Building Tower “C”, NYC, NY (2017-2018)

Scope: Embeds & AESS Podium Steel System

Hudson Yards-----Building Tower “A”, NYC, NY (2017-2018)

Scope: 68 Floors---Embeds for AESS Steel System

NYU Langone Medical Center—Kimmel Pavilion, NYC, NY (2016-2017)

Scope: AESS Steel Frame System

Alexander Court, Alexandria, VA (2016-2107)----

Scope: Entire Retro Clad System

Capital OneBuilding---Pennsylvania (2016-2017)

Scope: AESS Portal Steel System

56 Leonard Street, NYC, NY (2016)

Scope: Stainless Steel AESS Entrance System

Columbia University, Jerome L Greene Science Center— NYC, NY (2016)

Scope: Curtainwall AESS Steel System

St. Barnabas Hospital, Livingston, NJ (2016)

Scope: Embeds & AESS Podium Steel System

VIA—57 West, NYC, NY (2015)

Scope: Sub-truss AESS Steel System

NMAAHC—National Museum of African American History & Culture (2014-2016)

Scope: Entire Truss AESS Steel System for Façade---Winner of numerous WBC awards

432 Park Avenue, NYC, NY (2015)

Scope: Curtainwall Support Steel---Major AESS Mullions

Children’s Hospital of Philadelphia (CHOP)l Buerger Center for Advanced Pediatric Care, Phila, PA (2015)

Scope: Curtainwall Support Steel---Major Mullions---

250 W.55th Street, NYC, NY (2014)

Scope: Exterior AESS Sunshade Fins----every floor

United Nations Plaza, NYC, NY (2014)

Scope: Retro-Clad AESS exterior ---Major Mullions

Fulton Center, NYC, NY (2014)

Scope: Major Mullions---Misc steel--AESS

John Jay College, NYC, NY (2013)

Scope: Podium Steel---Major Mullions—hundreds AESS members

4 World Trade Center, NYC, NY (2012-13)

Scope: Blast-Resistant Category #1 Podium Steel---Major Mullions---“Largest Ever Made” ---506 members

Contractor: Benson Global/Tishman

United Nations Building, NYC, NY (2013)

Scope: Stainless Steel Exterior Mullions---Major Mullions Materials

Contractor: Enclos Corp

One World Trade Center, NYC, NY (2011-12)

Scope: Curtainwall parts & Assemblies; also made stone anchoring systems (all floors)

Contractor: Benson Global/Tishman

51 Louisiana Avenue, Washington, DC (2008)

Scope: Sky Framing System; Massive Frames for Glazing; Innovative Engineering for Enclosing Inter-Building Courtyard

Contractor: Enclos Corp

BWI International Airport, Washington, DC (1998)

Scope: 40,000 structural tubes (millimeter precision) w/ full penetration welds for 200,000 sq ft atrium space frame. ZERO rejections or remediations. Architectural type fabrications as additional components to space frame materials. Miscellaneous machined anchors (stainless steel, aluminum) finished as specified (polished, Tnemec paint or hot dip galvanized). All structural members, re-enforcement metals and skylight connections (such as saddle brackets, wind load anchors, etc.) Over 200,000 lbs. of fabricated “purlin” items (Beam and Channel w/ welded angles and plates, holes, slots, miters, etc.) to accommodate the skylight connections.

Contractor: Harmon Inc./Clark

Novartis Pharmaceuticals Headquarters, Florham Park, NJ (2012)

Scope: AESS Exterior Façade---to Frame Glass Block Wall and Curtainwall Support Steel

Contractor: Benson Global/Turner

Newseum, Washington, DC (2011)

Scope: Polished Stainless Steel Assemblies and Curtainwall Support Steel

Contractor: Enclos Corp/Clark

Barclay Center, Brooklyn, NY (2011)

Scope: AESS Truss Fabrication; Misc Steel painted Components

Contractor: FacadeTech

VCU New Medical School, Richmond, VA (2011)

Scope: AESS Painted Steel Mullions

Contractor: Harmon Inc./Clark

255 W.54th Street Building, NYC, NY (2011)

Scope: AESS materials for 53 Floors---Stainless Steel brake metal Material

Contractor: Enclos

Javits Convention Center, NYC, NY (2010)

Scope: AESS-Fabricated Steel Supports and Anchoring System

Contractor: Enclos/Bovis

American Jewish Heritage Museum, Philadelphia, PA (2010)

Scope: AESS- Exposed Façade Steel Anchoring System

Contractor: J. E. Berkowitz

New York Times Building, NYC, NY (2010)

Scope: AESS-Fabricated and painted “Cafeteria” Steel-----14th Floor-all exposed to frame huge windows

Contractor: Benson Global/Bovis

Madison Square Garden, NYC, NY (2010)

Scope: AESS- Stone Truss System

Contractor: Stone Truss

CitiField, NYC (Queens), NY (2009)

Scope: AESS- Stone Anchoring System

Contractor: Port Morris

BRAC Center, Carroll County, MD (2009)

Scope: AESS Truss System for Window Supports

Contractor: IKON/Clark

Constitution Center, Washington, DC (2008)

Scope: Misc. Heavy Curtainwall Brackets

Contractor: Enclos Corp

New Yankee Stadium, Bronx, NY (2008)

Scope: AESS- Stone Truss System

Contractor: Stone Truss

Center of Morris County, Florham Park, NJ (2007)

Scope: 325 Complete Trusses with all field hardware. Painted and delivered.

Contractor: Stone Truss Systems

15 Central Park West, New York, NY (2007)

Scope: Glass Curtainwall Anchoring System

Contractor: Benson Global

Washington Visitors Center, Washington, DC (2006)

Scope: Custom Stainless Ancho

Lorton Contracting/ Manny Sierra

New York Times Building, New York, NY (2005-2007)

Scope: Custom Fabricates water jet shapes with Acrylic paint.

Work value over $225,000.00

UVA Arena, Richmond, VA (2004-2005)

Scope: Providing Custom Steel Wind bracing.

Work value over $259,000

Borgota Casino Expansion, Atlantic City, NJ (2005-2006)

Scope: Curve Tubes Clad in Stainless for Casino Entrance.

Work value over $ 198,000

APG Glass/ Eric Rosenberg

CIRA Center, Philadelphia, PA (2005-2006)

Scope: Glass Façade AESS Steels Parts

Work value over $175,000

731 Lexington Ave, New York, NY (2005)

Scope: AESS steel parts for Curtainwall; Canopy entrances above the storefront.

Astor Place, New York, NY (2005-2006)

Scope: Provided category 3 architecturally exposed radius tubing. Supplied custom curtainwall anchors.

7 World Trade Center, New York, NY (2005-2006)

Scope: Provided AESS steel truss frames for the interior granite installation. Over 10,000 Stainless Steel Anchors for the granite installation.

Scope: Provided approx. 22,000 black anodized stainless anchors for hand-set stone cladding of this signature building. Anchors are anodized black in order to reduce their visibility in the open joint stone façade. Work value approx $120,000.

Borgata Casino Hotel (Porte Cochere Skylight), Atlantic City, NJ (2002-2003)

(GC Yates / Tishman, Owner Marina District Development Corp., Architect Bower Lewis Thrower (Philadelphia) and Cope Linder Associates (Philadelphia)) (JV)

Scope: Providing tube steel supports for entry drive. HSS steel is hot dip galvanized and subsequently clad with polished stainless sheet to appear as solid structural stainless. Largest members are 65’ curved segments. Work value approx $400,000.

West Perry Condominiums, West & Perry Street, NY, NY (2001-2002)

(Architect Richard Meier & Ptrs, GC: Gotham Const Corp

Scope: Provided significant quantities of AESS curtainwall support steel and custom flashing for this ultra-luxury residential building. Our work included modifications to European hardware to make it work given varying field conditions.

Philadelphia International Airport Terminal 1, Philadelphia, PA (2001)

(Architect Kohn Pederson Fox Associates)

Scope: Provided curtainwall support steel for metal panel cladding of new international arrivals terminal. Work value approx. $450,000.

State Farm Corporate Complex, Morristown, NJ (2000)

(Architect Gerald A. Voermans, GC/ Owner Gale Wentworth Associates)

Scope: Fabricated 400 truss frames (38,000 sq.ft.) for class A office building.

Gannett / USA Today Corp. Headquarters, McLean, VA (2000)

(Architect Kohn Pederson Fox Associates, GC Clark Construction)

Scope: Fabricated / high-performance painted 80 tube steel supports (43-ft x 8” x 20” x ½” thick wall) for long-span curtainwall. Also supplied 90 barrels of connection hardware. Work value approx $450,000.

Schering Plough K-1 Laboratory, Kenilworth, NJ 2000

Scope: Fabricated 95 truss frames (16,000 sq. ft.) under extremely tight deadline for new pharmaceutical laboratory complex. Worked closely with both Metro Framing Systems, Inc. and general contractor Torcon Construction while attempting to salvage building closure date. Work value approx $290,000.

Islip Federal Courthouse, Islip, NY 1999

Turner Construction (Architect Richard Maier, Owner GSA)

Scope: Detailed and fabricated 135 truss frames (22,000 sq. ft.) for wing wall portion of justice complex. We were replacement subcontractor for Metro Framing Systems, Inc. Turner Construction was extremely pleased with the “rescue” by Metfab and we became an approved subcontractor for Turner. Located in Central Islip, adjacent to the existing county courthouse, this federal courthouse takes advantage of panoramic views over both Great South Bay and the Atlantic Ocean. Designed in a partnership with Richard Meier & Partners, the 12-story building was placed on a podium to give it a presence on an otherwise flat and undifferentiated exurban site.The north façade is faced with stone and pierced by horizontal windows. This building reinterprets the courthouse type to enable it to function as a new kind of civic institution, receptive to public events as well as to the formalities of the judicial process. The structure, one of the tallest on Long Island, is meticulously organized to accommodate as many proceedings as possible. Measuring in at 870,000 sq. ft., the facility houses 23 separate courtrooms, 24 judges' chambers, a law library, office space for several Federal agencies and a cafeteria

Dulles Airport Project, Chantilly, VA (1998)

Scope: Terminal expansion – provided all miscellaneous fabricated tube steel for roofline facade, as well as parts for metal enclosures, wind screens, and ground screen walls.

Secret Service Building, Washington, DC (1998)

Scope: Miscellaneous steel framing. Tube steel truss frames with various angle and plate cross members.

Basilica National Cathedral, Washington, DC (1998)

Scope: Fabrication of 80’ long / ¾” thick stainless steel sub-structure supporting world-renowned 50 ton hand-carved stone sculpture of religious figurines.

J.P. Getty Center Project, Los Angeles, CA (1997)

(Architect: Richard Maier)

Scope: Various angles and stainless steel anchors required. Various welded anchors. High performance coatings such as Tnemic and Ameron-Amerlock.

Washington National Airport, Washington, DC (1997)

Scope: Miscellaneous skylight metal stripping, window lifting racks and custom frames (made of angles, tubes, plates, etc.) provided.

Church of Latter-Day Saints Cathedral, Caracas, Venezuela (1997)

Scope: Typical stainless steel handset anchors with various hardware items (nuts, bolts, dowels, etc.) provided. Under an extremely tight schedule, Metfab produced nearly 10,000 anchors (welded items included) within six days. Metfab’s first involvement with international trade.

International Monetary Fund, Washington, DC 1997

Enclos Corp

Scope: "Entrance Way" materials. 30'-0" long hot-dipped galvanized framing and approx. 6,000 pcs. of various welded stainless steel clips.

Virginia State Library Project, Richmond, VA (1996)

Scope: Cosmetic Stainless Steel Shapes. Provided approx. 35 pcs. 1/2" thick x 20" wide x 12'-0" long stainless steel custom anchors, welded as required. All Polished to #4 brush finish as required. Also various custom handset anchors.

Chanel, New York City, NY (1995)

Scope: Approx. 20,000 pcs. supplied of various stainless steel welded anchors 3/8", 1/2" and 5/8" thick and all miscellaneous hardware.

Ronald Reagan Building (Federal Triangle Project), Washington, DC 1995

(Designer Pei Cobb Freed & Partners)

Scope: Stainless Steel Plug Anchors (various sizes and designs), approximately 25,000 pcs. supplied. Hot Dipped Galvanized Disc Anchors, approx. 35,000 pcs. Handset Clip Anchors (various angles, plates, tubes, etc. - all shot-blasted and painted per specifications provided), approx. 30,000 pcs. Field Connections: Deadloads with Jack nuts (800 pcs), Landing Seats and Embeds (approx. 20,000 pcs.) and Field Fixes. Erection hardware including picking materials, frames for stone transporting, and more. Over 300 "hot-rush" conditions successfully accommodated. Over the term of the project, our involvement in the many aspects of the job enhanced our capabilities as a complete manufacturing facility and provided us with experience in running tight schedules, accommodating different conditions and applications and tracking procedures.

Foley Federal Square Project, New York City, NY (1994)

Scope: Provided approx. 200 custom steel frames for 80' raised rotunda (upper and lower) and 50,000 miscellaneous stainless steel anchors.

Merck Pharmaceutical, Readington, NJ (1991)

Scope: All miscellaneous steel members and frame components (approx. 200,000 pcs.) All loading and picking platforms for erection. All gutter systems for drainage.